Recent studies have revealed that brewing tea with conventional tea bags may release billions of microplastic particles into the drink. Since tea bags, coffee filters, and similar products are often exposed to high temperatures during use, the safety and environmental impact of their materials have become a growing concern.

Polylactic acid (PLA) fiber, derived from renewable resources like corn starch, has emerged as a promising alternative. Referred to as the “corn-based tea bag,” PLA provides a biodegradable and safer solution for everyday use.

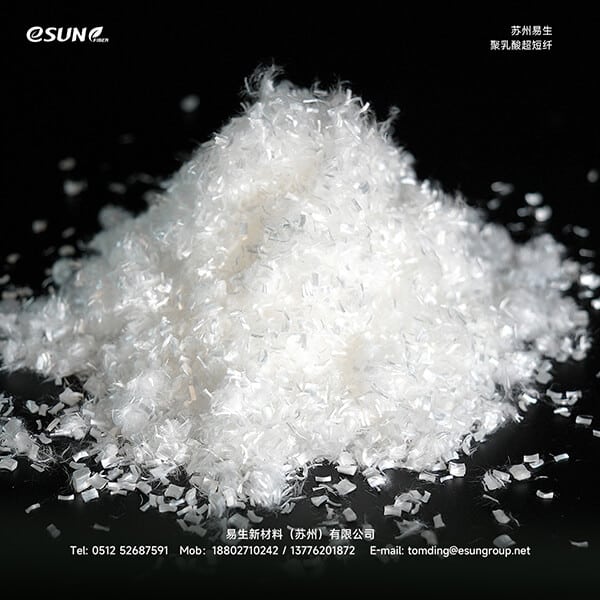

Introduction to eSUN’s PLA Super Short Cut Staple

Specifications: Fineness: 0.9–6D | Lengths: 3mm, 5mm, 6mm, 12mm

eSUN, based in Suzhou, offers a range of PLA Super Short Cut Staple fibers designed for integration into specialty papermaking processes such as wet-laid and dry-laid methods. These fibers are particularly well-suited for use in biodegradable and compostable paper products, including:

- Tea bags

- Coffee pods and filter paper

- Herbal sachets

- Spice infusion bags

- Foot bath packs

- Dust-free wipes

- Eco-friendly packaging papers

Performance and Technical Advantages

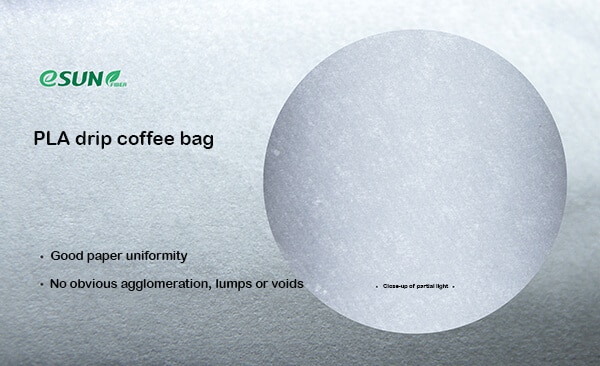

Despite PLA’s inherent hydrophobicity, which traditionally makes dispersion in water difficult, eSUN has developed customized PLA Super Short Cut Staple fibers that significantly improve compatibility with other cellulosic fibers in the slurry. This advancement reduces clumping and enhances fiber uniformity during sheet formation, ensuring consistent product performance.

Key Benefits of Using PLA Super Short Cut Staple in Specialty Paper:

1. 100% Bio-Based and Fully Biodegradable

PLA fibers naturally break down into carbon dioxide and water under composting conditions, thanks to microbial activity. With billions of disposable tea bags used daily around the world, PLA-based options offer a meaningful step toward reducing plastic waste and easing environmental pressure.

eSUN PLA fibers and related nonwovens are certified under DIN standards for biodegradability.

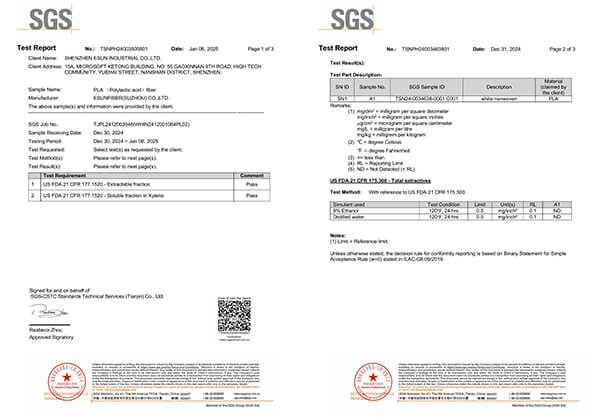

2. Food-Safe and Microplastic-Free

Derived from renewable plant-based sources, PLA is a certified food-contact material. Unlike traditional plastic fibers that may release harmful substances when exposed to hot water, eSUN’s PLA fibers remain inert and safe. This makes them ideal for applications in direct contact with food and beverages, such as tea and coffee brewing.

eSUN PLA fibers and nonwovens meet FDA food safety standards.

3. Heat-Sealable via Ultrasonic Bonding

When incorporated into specialty paper, eSUN’s PLA fibers allow for ultrasonic thermal bonding, eliminating the need for adhesives. This enhances manufacturing efficiency and maintains product purity.

eSUN’s PLA bicomponent fibers use a sheath-core design: the outer sheath is soft and has a low melting point, while the inner core is stronger and heat-resistant. This dual-layer structure allows the fiber to replace traditional bonding agents like PP and PET in heat-seal applications, offering a truly glue-free, all-PLA, biodegradable solution.

4. Easily Blended with Other Natural Fibers

PLA Super Short Cut Staple can be blended with wood pulp, nanocellulose, or other plant-based fibers to enhance sheet formation. It acts as a structural enhancer and binder under heat, improving the final product’s mechanical properties. Through formulation adjustments, eSUN can support customized solutions tailored to different performance or application needs.

The Future of Specialty Paper with PLA

By integrating PLA Super Short Cut Staple into specialty papers, manufacturers can meet sustainability goals while delivering safe, high-performance products. From environmental protection to product functionality, PLA stands at the intersection of innovation and responsibility.

We welcome collaboration from partners across the globe to explore new possibilities in bio-based specialty paper. Contact eSUN to learn more about our fiber solutions.