Polylactic acid (PLA) fiber has gained popularity as a filling material, particularly in hollow fillings, due to its unique combination of environmental and functional benefits.

PLA Fiber Filling

hollow fiber filling

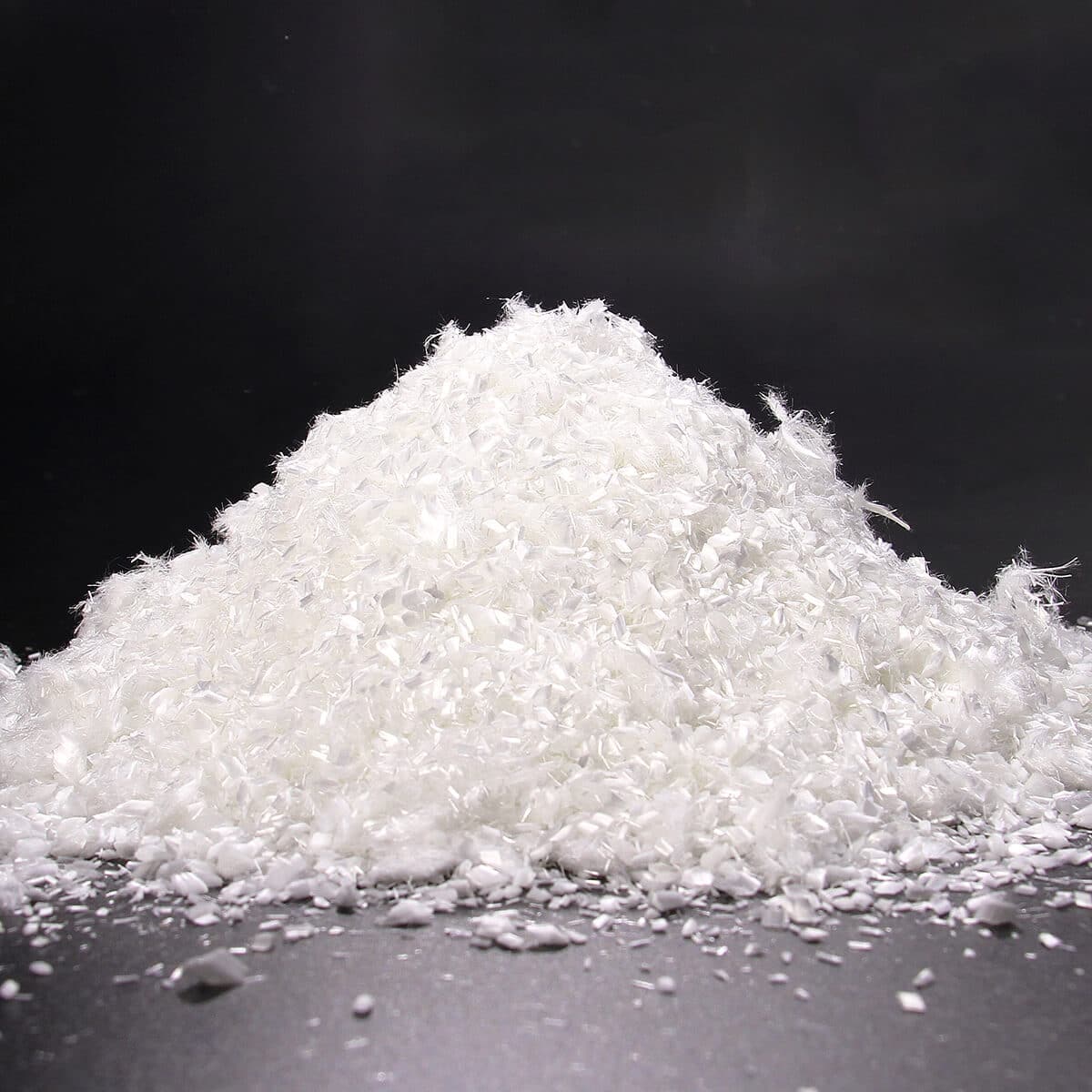

Product Description

Polylactic acid (PLA) fiber is a biodegradable and eco-friendly material made from renewable resources like cornstarch or sugarcane,It is also known as corn fiber.

When used as a hollow filling material, PLA fibers offer additional benefits. The hollow structure enhances thermal insulation and lightweight properties, making it ideal for applications like bedding, jackets, and outdoor gear. The air trapped within the hollow structure helps retain warmth while keeping the material light and breathable.

PLA fibers also exhibit excellent moisture-wicking and hypoallergenic properties, ensuring comfort and safety for sensitive users. Additionally, they provide good resilience and softness, maintaining their shape and comfort over time.

PLA fibers, especially when used in hollow fillings, provide a sustainable, lightweight, and highly functional solution for various industries, all while supporting environmental responsibility.

Home Textiles

Examples: Pillows, cushions, comforters, mattresses.

- Softness and Loft: PLA fiber provides a plush and luxurious feel, ideal for creating soft yet supportive bedding products. Its hollow structure ensures the material maintains its loft, giving pillows and cushions a fluffy and voluminous appearance.

- Moisture-Wicking: Its moisture-wicking properties help keep bedding dry and comfortable, especially important in humid environments.

- Hypoallergenic: PLA fiber is naturally resistant to allergens, making it a safe choice for sensitive individuals or those prone to allergies.

Toys

Examples: Stuffed animals, dolls, plush cushions.

- Safety: PLA fiber is free of harmful chemicals and hypoallergenic, ensuring it’s safe for children to play with and snuggle.

- Softness and Durability: The material is soft to touch yet resilient, meaning stuffed toys remain huggable and maintain their shape even with rough handling.

- Eco-Friendly Appeal: Parents and manufacturers increasingly prioritize sustainable materials for children’s products, and PLA fiber fits the bill perfectly as it is biodegradable and made from renewable resources.

- Washability: PLA fiber can withstand regular washing, keeping toys clean and fresh over time.

Warm Clothing

Examples: Jackets, winter coats, thermal wear.

- Lightweight Warmth: The hollow structure of PLA fiber traps air effectively, providing excellent insulation without adding extra weight. This makes it ideal for outdoor and winter wear where warmth and comfort are essential.

- Breathability: PLA fiber allows moisture to escape, preventing overheating and keeping the wearer dry and comfortable during physical activity or varying temperatures.

- Shape Retention: Jackets and thermal wear filled with PLA fiber maintain their shape and insulating properties even after repeated use or compression.

Certifications

Why choose us?

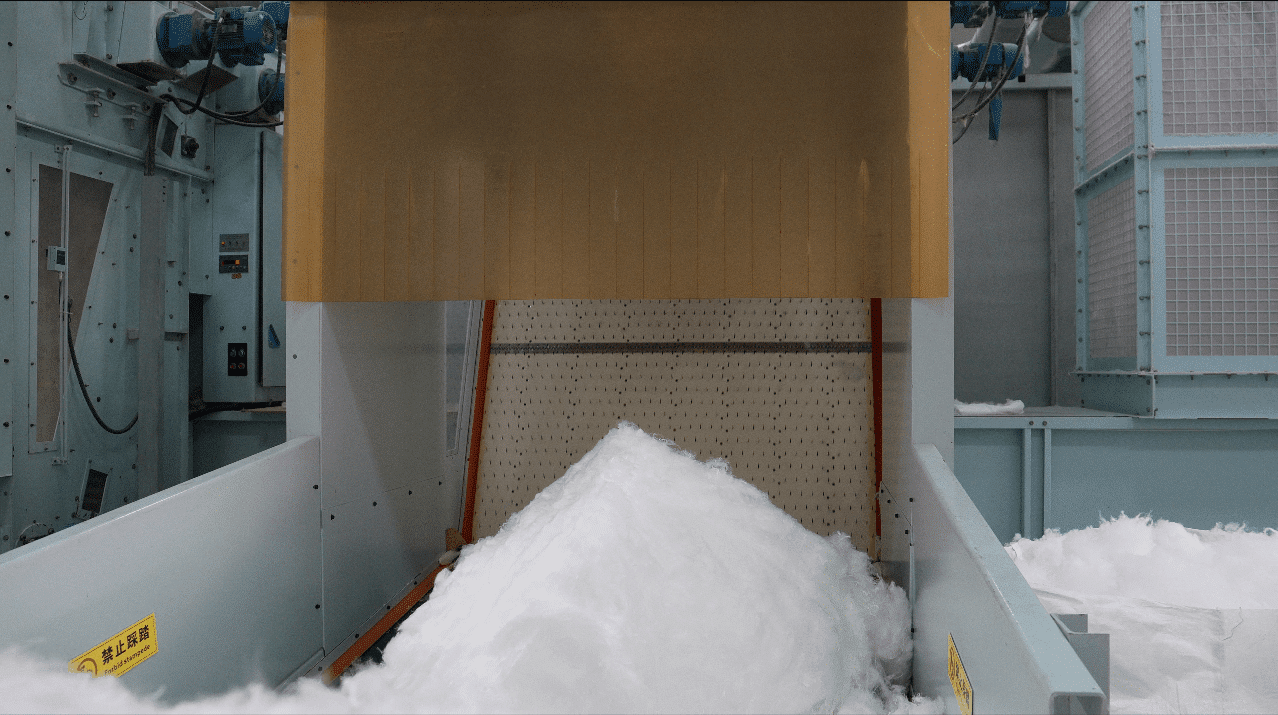

eSUN specializes in producing polylactic acid (PLA) fibers and non-woven fabrics, maintaining a leading position in the industry. PLA bicomponent fiber stands out as the company’s signature product, with large-scale production and sales already achieved.

The company’s current production capacity includes a 10,000 tons/year melt direct spinning polylactic acid fiber production line, a 1,000 tons/year polylactic acid hot air & hot rolled non-woven fabric production line and three functional polylactic acid fiber production lines.