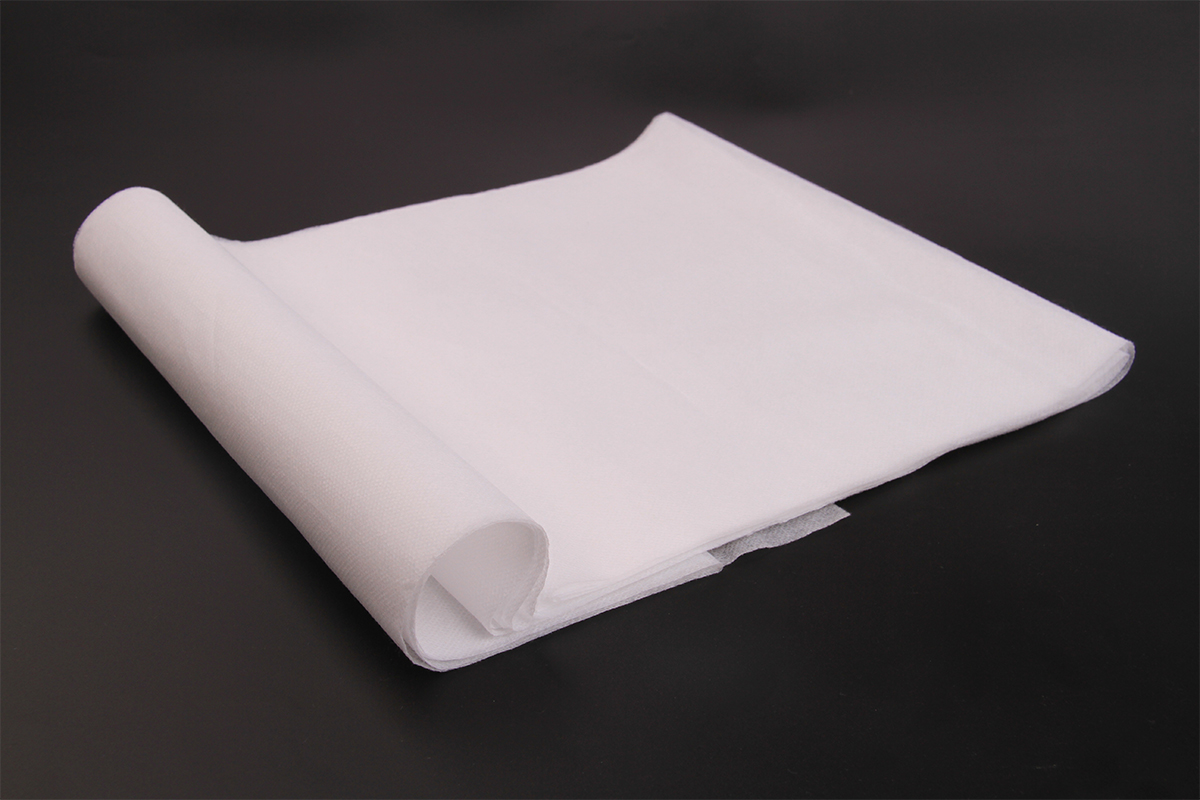

PLA Bi-component Staple

Specification: Titer: 1.5Denier-5Denier,

Length:6~64mm

Application: Non-woven fabrics/thermal

bonding/fillers. etc

Specification: Titer: 1.5Denier-5Denier,

Length:6~64mm

Application: Non-woven fabrics/thermal

bonding/fillers. etc

PLA Bi-component Staples are eSUN’s leading and specialized product with mature production technology and stable quality. This product is a bi-component sheath-core structure composite fiber, made from 100% PLA. The sheath layer is composed of low-melting-point PLA with good softness, while the core layer is composed of high-melting-point PLA with high strength. After heat treatment, part of the sheath layer melts and acts as a bonding agent, while the remaining part retains its fibrous structure. The fibers interconnect with each other, forming a nonwoven fabric without the need for adhesives. Additionally, the fiber exhibits low thermal shrinkage characteristics.

PLA bi-component staple offers excellent biocompatibility, dryness, breathability, antibacterial and deodorizing features, as well as biodegradability.PLA bi-component staples are further processed into various forms of non-woven fabrics, such as Air Through,Thermal Bonded,Spunlaced,Needled,Spunbonded and Meltblown Non-woven Fabrics,and are used in fast-moving consumer goods, packaging materials, and medical supplies.

PLA Bi-component Staple is an excellent fiber for thermal bonding, primarily used in the thermal bonding process of non-woven fabrics. Unlike “area bonding,” this method focuses on “point bonding,” which results in a product that is bulky, soft, strong, and capable of absorbing oil and blood, among other properties.PLA bi-component staple can also be applied to filter materials, gardening household materials, insulation materials, adsorption materials, packaging materials, and padding, etc.

PLA Bi-component Staples are highly suitable for use as fillers in products such as flakes, stuffed toys, and mattresses. Their inherent qualities, including natural drying, antibacterial, and deodorizing effects, make them particularly advantageous for applications in baby products, elder care products, and pet products.

PLA Bi-component Staple include filter materials, horticultural domestic materials, insulating materials, adsorptive materials, packaging materials, rigid fiberboards, automotive wall materials, and padding materials, among others.