As a globally influential event in the nonwovens industry, the IDEA 2025 Exhibition will take place in Miami from April 29 to May 1. This triennial gathering serves as an important industry indicator, where eSUN will present its complete range of bio-based PLA fiber solutions for sustainable nonwoven applications.

1.PLA Air Through/Thermal Bonded Non-woven Fabric

Air through bonded non-wovens demonstrate outstanding characteristics including high bulkiness, excellent elasticity, soft texture, and superior breathability. These properties make them ideal for disposable sanitary products such as diapers, adult incontinence products, and feminine care items, as well as household disposables like napkins and tablecloths. Heavier versions are used in thermal clothing, bedding, and home furnishings, while high-density thermal bonded variants serve specialized functions in filtration and sound absorption.

Example of eSUN’s PLA thin air through non-woven fabric

Thermal bonded PLA non-wovens offer softness, breathability and biocompatibility, making them suitable for medical protective equipment including masks, surgical gowns and nursing pads. They also excel in eco-friendly packaging applications such as food bags, shopping bags and gift wrapping, while serving agricultural purposes as ground covers and plant protectors.

Custom color options (including medical blues and greens) are available through specialized spinning or dyeing processes.

Application example: Peach preservation packaging

2.PLA Needled/Spunlaced Non-woven Fabric

eSUN’s PLA spunlaced non-wovens are widely used in sanitary products including diaper components, cosmetic wipes and facial masks, benefiting from their excellent biodegradability and breathability. These materials also show promise in sustainable packaging and agricultural applications.

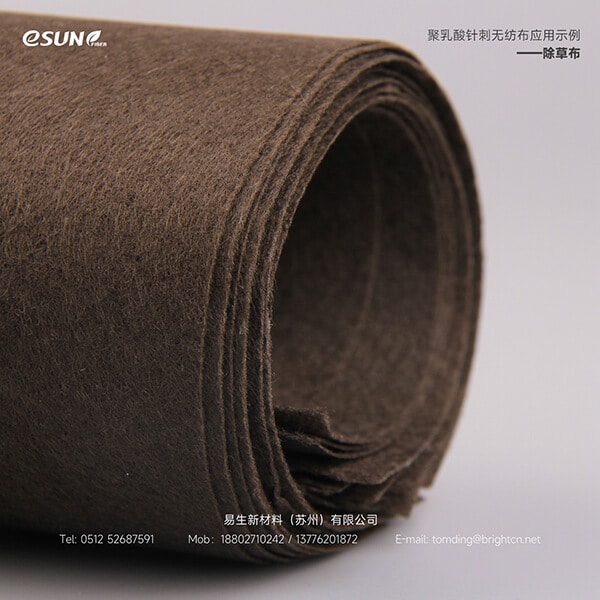

The needled versions demonstrate particular value in geotextile applications (erosion control, infrastructure projects) and agricultural uses (weed control, plant protection). Their unique combination of durability and environmental benefits makes them suitable for:

- Slope stabilization in construction

- Drainage systems in civil engineering

- Horticultural applications (planting bags, crop covers)

Application examples:

- Agricultural weed control fabric

- Plant growth bags

3. PLA Bicomponent Staple/Hollow Fiber/3D Crimped Staple/Staple Staple

eSUN is dedicated to the research, development, production and sales of PLA fibers and non-woven fabrics. The company offers a comprehensive range of PLA fiber products including various specifications of staple fibers, filament yarns, and non-woven fabric materials.

The PLA staple fiber product line includes:

- Conventional staple fibers

- Super short cut staples

- Bicomponent staples

- 3D crimped staples

- Colored spun yarns

- Profiled cross-section fibers

- Functional specialty fibers

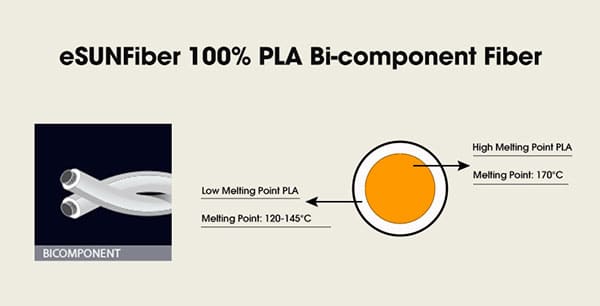

Among these, the PLA bicomponent staple stands out as eSUN’s flagship product. This innovative solution combines with natural fibers (hemp, cotton, wool) or regenerated cellulose fibers (viscose, lyocell, modal, bamboo fiber) to replace conventional low-melt polyester fibers and ES fibers in nonwoven applications. The technology achieves complete material degradability while providing more environmentally sustainable solutions for product upgrades. Furthermore, PLA bicomponent staple can effectively replace ES fibers as a bonding agent when combined with natural or regenerated fibers.

Non-woven fabrics have become increasingly prevalent in daily life and industrial applications. The development and adoption of bio-based fiber materials like PLA contributes significantly to sustainable economic and environmental progress. We cordially invite both new and existing partners to visit our booth at IDEA 2025 to explore the innovative applications of PLA fibers and non-woven fabrics. Our technical team will be available to discuss customized solutions and potential collaborations.